Anvils have been around for centuries and are still commonly used in blacksmithing and metalworking. They are heavy blocks of metal that are used as a surface for shaping and manipulating various materials, such as iron and steel. But how are anvils forged? Let's take a closer look.

What is an Anvil?

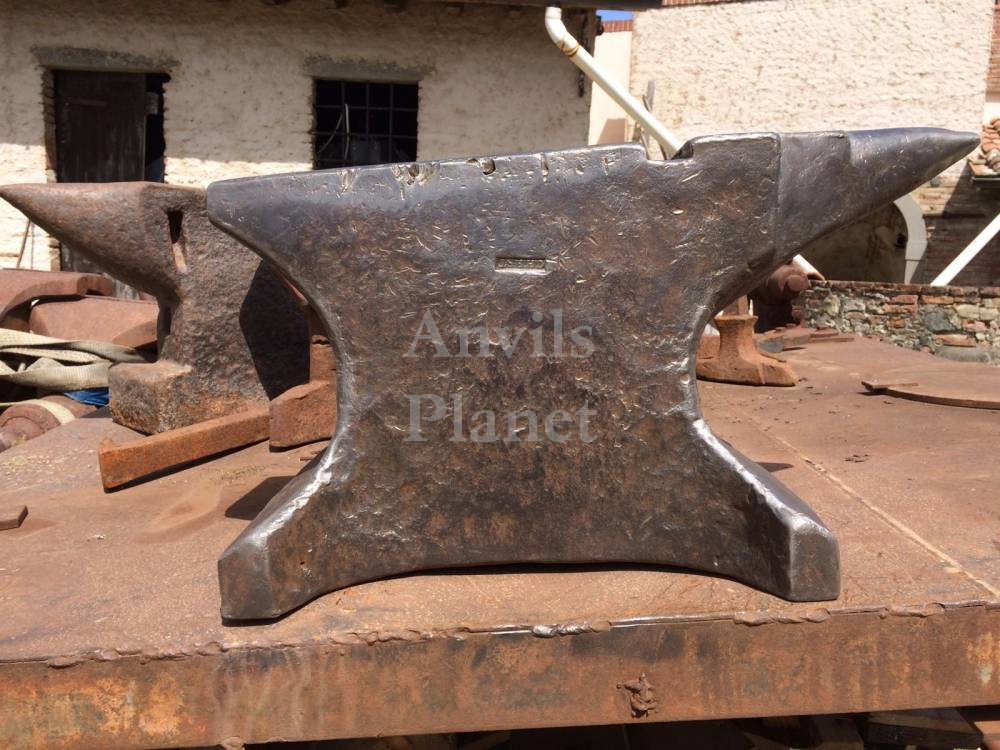

An anvil is a heavy block of metal, usually made of steel or iron, that is used by blacksmiths and metalworkers to shape and manipulate various materials. It typically has a flat top surface, with a horn and a heel, which are used for different types of shaping and forming.

How Are Anvils Made?

Anvils are made through a process called forging, which involves heating metal to a high temperature and then shaping it using a hammer and an anvil. The metal used for forging an anvil is typically a high-grade steel or iron alloy, which is chosen for its durability and strength.

The Forging Process

The forging process begins by heating the metal to a high temperature, typically around 2,200 degrees Fahrenheit. Once the metal is hot enough, it is placed on an anvil and shaped using a hammer. This process is repeated multiple times until the desired shape and size is achieved.

The Finishing Process

Once the anvil has been forged into its final shape, it is then finished by grinding and polishing the surface. This process helps to ensure a smooth and even surface, which is essential for accurate and precise metalworking.

Types of Anvils

There are several types of anvils available, each designed for specific types of metalworking. Some common types of anvils include the London pattern anvil, the farrier's anvil, and the double horn anvil.

The London Pattern Anvil

The London pattern anvil is one of the most common types of anvils used in metalworking. It has a flat top surface, a horn on one end, and a heel on the other. The horn and heel are used for different types of shaping and forming, while the flat surface is used for general metalworking.

The Farrier's Anvil

The farrier's anvil is a type of anvil that is specifically designed for horseshoeing and other types of equine work. It typically has a wider base and a more curved horn than other types of anvils.

The Double Horn Anvil

The double horn anvil is a type of anvil that has two horns, one on each end. This allows for more flexibility in shaping and forming various materials. It is commonly used in metalworking and blacksmithing.

Conclusion

Anvils are essential tools in metalworking and blacksmithing, and are still commonly used today. Through the process of forging, these heavy blocks of metal are shaped and formed into their final shape, and then finished to ensure a smooth and even surface. With several types of anvils available, each designed for specific types of metalworking, there is an anvil available for any job.